Basic Information of using the Industrial Air Brakes

In industrial

applications, there is a need for braking due to different reasons.

Braking is the

process of controlling the speed of an object by preventing it from moving. An

object in motion has kinetic energy and this kinetic energy must be removed to

stop the object. Removal of kinetic energy can be accomplished by spreading

energy into the atmosphere through friction or by converting it into another

form of energy.

The most common

type of brake is a mechanical brake that prevents movement through friction

brake pads. A mechanical brake applies a frictional force to convert the

vehicle's kinetic energy into thermal energy which then dissipates into the

atmosphere.

As with any system, the braking process must follow the conservation of energy principle. Energy cannot be created or destroyed, it can only be transformed from one form to another, Using the compression force of the compressed air, braking with a holding force is a common and safe method.

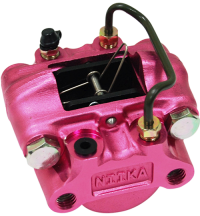

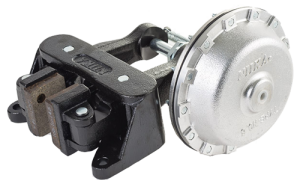

Pincer type air

brakes called calipers are called air braking with spring opening positive type

and spring braking with air opening type as negative type braking.

We can list four

different braking methods according to the machine's construction, working

environment and the purpose of use of the brake.

• Static braking;

• Emergency

braking;

• Continuous

braking;

• Cyclic

(intermittent) braking.

Correct safety

coefficients should be selected in the selection of brakes, taking into account

the current legislation and regulations.

In the selection of

the brake, the coefficients determined for the facility, machine and safety are

important, these values are specified in the manufacturer's catalogs.