Cage Ball Technology

SHS type linear motion systems, which are developed as an alternative to HSR classic type products, constitute the end point in the search for maintenance-free machinery produced by THK's patented “cage ball” technology . It is known that maintenance-free machines are preferred in the world market.

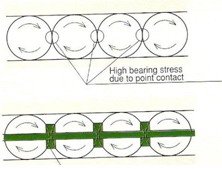

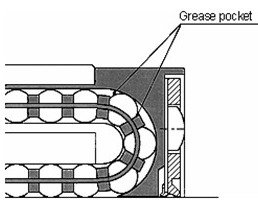

• Thanks to the grease pouches between the balls, direct contact of the balls is prevented and the features such as abrasion and friction are reduced to the lowest levels.

• Since friction is at 1 in 10 levels compared to conventional systems, it has excellent speed performance and generates low heat.

• Due to the grease retention of the balls, it does not require long-term maintenance and the dust distribution is low, ie it does not hold dirt.

• Noiseless operation at high speeds.

• Energy consumption is reduced to the lowest levels.

• They have a much longer life than conventional systems.

• Since the grease bags between the balls are also in a special housing, they work regularly and smoothly.

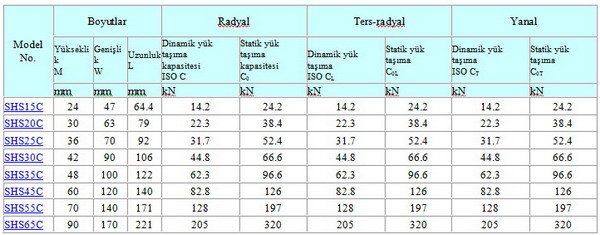

A comparison of the

conventional load carrying capacity of HSR 25 with SHS 25 and cage-ball type 25 is as follows: HSR25A SHS25C (HSR25A equivalent cage ball car)

Dynamic C: 19.9 kN Dynamic C: 31.7 kN

Static C0: 34.4 kN Static CO: 52.4 kN

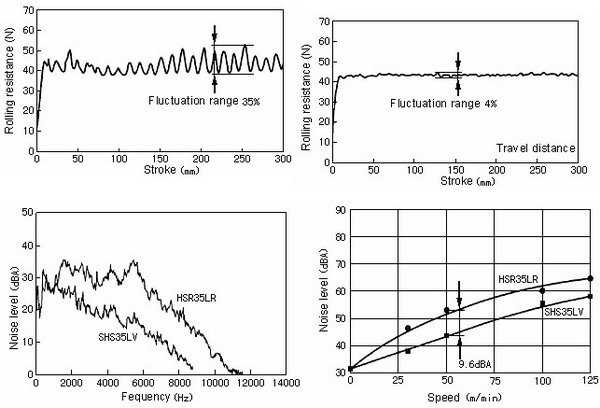

Below are the graphs comparing the noise, friction characteristics of HSR and SHS type products.