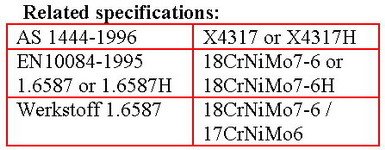

Case Hardening Steel - 18CrNiMo7-6

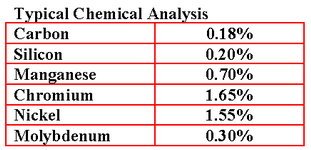

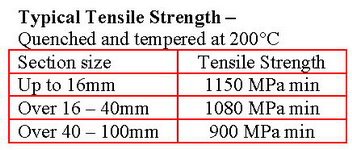

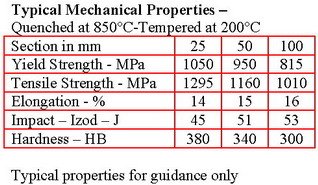

17CrNiMo6 or 18CrNiMo7-6 is a Chrome – Nickel – Moly carburising steel, generally supplied annealed to HB 229 max. Carburised and heat treated it develops a hard wear resistant case of about Rc 60-63 and a tough strong core with a typical tensile strength range of 900-1300 MPa, in small to fairly large sections.

Typical Applications: Heavy-duty arbors, bushings, bearings, gears, shafts, sprockets, wear pins etc. Or can be used uncarburised with suitable heat treatment for high tensile applications.

Machinability: Now available with improved machinability by calcium injection treatment.

Welding:

Readily welded in the annealed condition with correct procedure, but welding in the case hardened or through hardened condition is not recommended.

Welding procedure:

Low hydrogen electrodes recommended.

Pre-heat at

Welding details for guidance only

HEAT TREATMENT:

Forging:

Heat to

Minimum forging temperature

Cool in ashes, warm dry lime or sand

Annealing:

Heat to

Cool in furnace

Normalising:

Heat to

Cool in still air

Stress Relieving:

Heat to

Cool in still air

Carburising:

Pack, Salt or Gas carburise at

Core Refining:

Heat to

Cool in air or quench in oil or into a salt bath held at

Case Hardening:

Heat to

Quench in oil

Single Refine:

Suitable for fine grained steels only

Direct Quench:

Cool from carburising temperature to

Alternatively cool from carburising temperature to room temperature.

Re-heat to

Tempering:

Tempering at

Heat treatment details for guidance only